|

|

|

|

|

|

E10 digital display system

1. Prompt for one-way clearance of rear retaining material

2. X/Y axis screw error compensation

3. Soft limit function

4. Time relay

5. Counting function

|

RT200 CNC system

1. Dual-axis CNC device, economic CNC system

2. There is a computer for precision positioning control of the whole system 1/0 and mechanical stopper and rear stopper

3. Easy operation, installation and maintenance

4. RT200 input 9 programs, each program can input 20 work steps. The system has full automatic, semi-automatic and manual functions

|

E18 CNC system

1. It can not only meet the CNC function of the machine tool, but also meet the accuracy control requirements

2. Adopt the mode of direct control of the motor, which has three purposes: simple operation, convenient installation and easy maintenance

3. 1-9 steps can be input, and the system can work in a single time, or the cycle control accuracy is 0.1mm

|

E20 CNC system

1. Apply frequency conversion control technology

2. Automatic positioning of electric rear stopper and upper slider

3. One-way positioning to eliminate screw drive gap

4. Automatic operation of multiple programs and automatic counting of processing quantity

5. Power-off memory, metric/English conversion

|

MD-11 CNC system

1. One-way positioning prompt of rear stopper

2. Screw pitch error compensation

3. Time relay function

4. Power failure memory

5. Metric/English conversion, counting function

6. Manual and automatic conversion

|

|

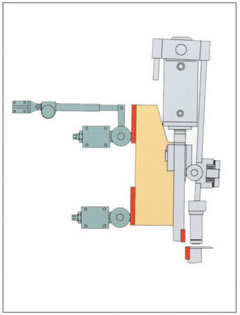

Schematic diagram of guide rail:

The three-point roller guide rail structure is adopted. Under the action of the disc spring knife, the front roller makes the tool rest stick to the side roller all the time to ensure that the tool rest moves up and down without gap and moves smoothly.

|

|

|

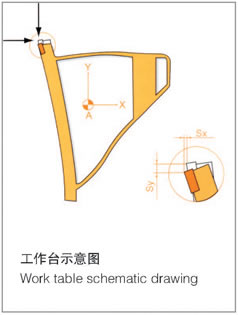

The unique worktable structure optimized by finite element design makes the deflection SX produced during the shearing process, which can compensate the deflection produced by the tool holder due to the effect of shearing force, so that the gap between the cutting edges of the machine in the full length direction is always uniform, and improve the shearing accuracy and quality

|

|

Copyright © Nantong Kingwell Machinery Co., Ltd